Leadership. Executive Capacity. Transparency in Management. 35 Years of Experience.

We know from our experience that each Project is unique, just as unique as each Customs Logistics Solution. And this is the reason why we have developed a working method that uses flexible Multimodal Services, based on sustainable logistics and customs principles supported by advanced systems of information technology, and allowing us to ensure a fast and efficient treatment of all operations throughout the Project.

Recent Projects

MEGA Project, Turnkey Plant, Bahía Blanca and Loma de la Lata Neuquén

Aluar Aluminio Argentino S.A. Turnkey Plant Puerto Madrid, Chubut

Aluar Aluminio Argentino S.A. Enlargement of Processing Plant, Abasto, Buenos Aires

Expansion of the Gas Transportation Capacity Project, Southern and Northern Gas Pipelines.

Magallanes Project, Offshore Gas Pipeline, Tierra del Fuego with Cabo Vírgenes, Santa Cruz.

Mina Pirquitas Project, Jujuy

AySA Agua y Saneamientos Argentinos S.A. "Juan Manuel de Rosas" Water Treatment Plant

AySA Agua y Saneamientos Argentinos S.A. "Del Bicentenario" Wastewater Treatment Plant

Biodiesel Treatment Plant Project ANCAP, Uruguay

"Bloque Santa Rosa" Gas Treatment Plant, Bolivia

"Tipei" Aircooler Plant, Peru

Ingentis, Dolavon Thermal Power Plant, Chubut

Odebrecht, Continuous Catalytic Reforming Plant Project CCR-YPF

Alcoa World Alumina Brasil Ltda. Ship Unloader Gantry Crane

IMPSA, Manuel Piar Hydroelectric Project (Tocoma) Venezuela

IMPSA, S.A.P.E.M. Arauco Wind Farm, La Rioja

Consorcio Nuevo Sarmiento CNS U.T.E. Undergrounding of Sarmiento Railway Line

TECPLATA S.A. Container Terminal at the Port of La Plata

SERVIMAGNUS S.A. - SDC BRASIL SERVICIOS MARITIMOS LTDA - ROWING S.A. -SERVIDRAGA S.A. UTE. Dredging of Mar del Plata and Buenos Aires Ports.

Energía Provincial Sociedad del Estado (EPSE) - SCHMID Group AG Turnkey Plant for Solar Panel Manufacturing.

In mid-1997,Compañía Mega S.A., formed by YPF S.A., Petrobras and Dow Argentina decided to carry out a project that would fully exploit natural gas. With a total investment of 715 million USD, it was the first Large Industrial Project in the Energy industry within the MERCOSUR.

The project involved the construction of two facilities: a sorting plant and a fractionation plant both connected by a 600-km pipeline spanning across four provinces.

The Sorting Plant is located in the heart of the Argentine natural gas deposit known as Loma de La Lata, in the province of Neuquén.

The Fractionation Plant is located within Bahia Blanca's Petrochemical Center, which is the largest one in Argentina.

ALUAR Aluminio Argentino SAIC is the only primary aluminum producer in Argentina and one of the largest in South America. It exports 85% of its output, mainly to the USA, the European Union and Asia.

In mid-2005, the company started the works to double its output capacity, with an investment of over 1,200 million USD. The first stage started in September 2007 and soon afterwards, the second phase took place, thus reaching an output capacity of 460,000 tons a year.

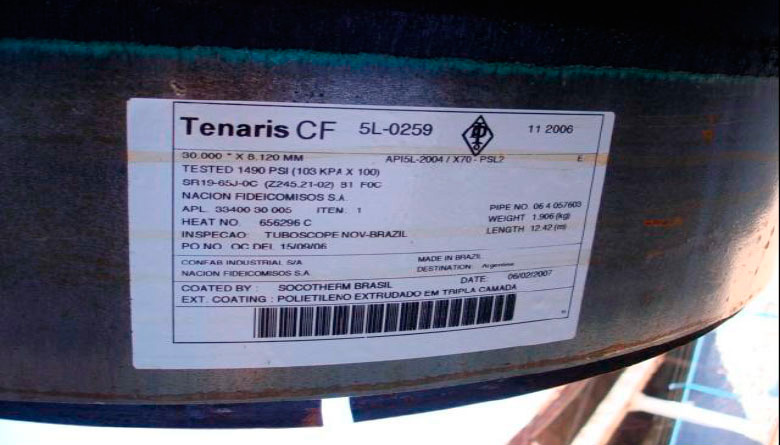

In 2006, Construtora Norberto Odebrecht started the Expansion of the Firm Gas Transportation Capacity, spanning across 15 provinces in Argentina.

The project includes the construction of new "loops" (pipelines segments, parallel to the existing ones) in San Martin and Neba II gas pipelines, operated by TGS (Transportadora de Gas del Sur), and in Northern gas pipelines, operated by TGN (Transportadora de Gas del Norte); and the construction of Compressor Plants along them.

The pipelines, with a total length of 1,889 km, divided into 84 loops and 20 Compressor Plants (construction and/or adjustments), have a power capacity of 248.3 KHP, and can transport 15.4 million cubic meters of gas per day.

Of the total planned investment, about 880 million USD were provided by the BNDES (Brazilian Bank for Economic and Social Development), as one of its major international operations. They consist in 2 trust agreements, one with Rafael G. Albanesi S.A. and another with CAMMESA S.A.

Until the end of the project, the work will involve more than 200,000 tons of pipes imported from Brazil.

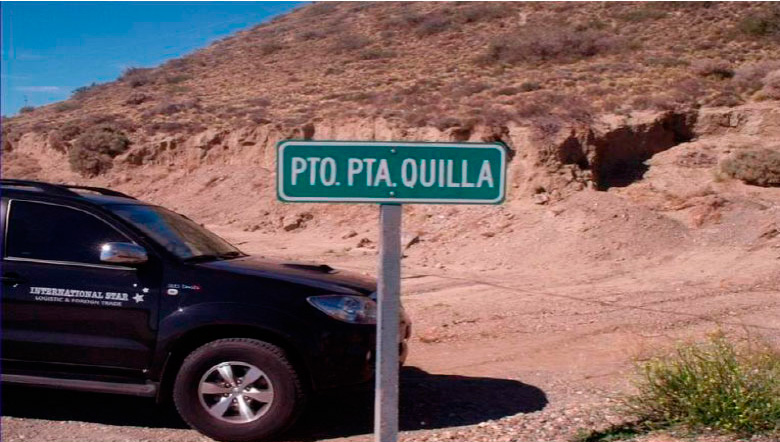

Total Cost of the Project: 320 million USD. Through the Port of Punta Quilla, in Santa Cruz, we shipped 38,000 meters of pipes (24 inches in diameter and 15.9 mm in thickness), including the anticorrosion and concrete coating of variable thickness, ranging between 70 and 130 millimeters, depending on the depth where each pipe would be installed.

In a historic crossing, Transportadora Gas del Sur undertook the challenge of laying a new 37-kilometer offshore pipeline, crossing the eastern mouth of the Strait of Magellan. These works were done in the context of a program developed by the Argentine Executive Power through the Energy Secretariat and ENARGAS, with the purpose of expanding the Firm Gas Transportation Capacity of General San Martín Gas Pipeline.

It is worth mentioning that this was the first time that Techint Engineering & Construction developed a complete Mining Project i.e. Management, Procurement Services, Commissioning, and Basic Engineering of an open pit mine. Its facilities can process 9,000 tons per day through flotation and gravity concentration. With Silver Standard Resources as the Client, and under an EPCM contract, the works included the execution of the civil and electrical infrastructure, the processing plant, the tailings dam and the mine infrastructure and service facilities.

Mina Pirquitas, located northeast of the Argentine province of Jujuy, has an estimated annual output of 9,000,000 ounces of silver, 2,300 tons of tin and 6,000 tons of zinc.

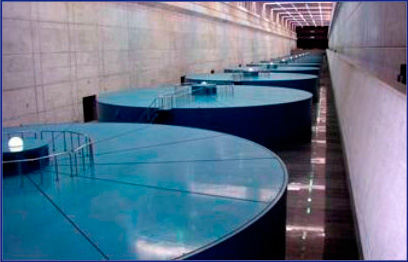

With an investment of 2,800 Million USD, the Plant located in Tigre will meet the current demand for drinking water as well as the future demand resulting from the planned expansion, while ensuring the necessary quality and quantity of water and allowing the temporary closure of the water ring in the concession.

The project includes the development of the work on three fronts: the construction on the intakes in Lujan and Paraná rivers, the construction of the plant, and the pipelines connecting the intakes with the plant and the plant with the water system.

With an investment of 500 million USD, the project includes the construction of a Water Sewage Treatment Plant in Berazategui, in the Province of Buenos Aires.

Biodiesel Treatment Plant Project ANCAP, Uruguay

"Bloque Santa Rosa" Gas Treatment Plant, Bolivia

"Tipei" Aircooler Plant, Peru

The main part of the project was shipped through the Port of Comodoro Rivadavia and then moved to the Free Zone, due to its suspension.

Odebrecht was awarded the construction of the first Continuous Catalytic Reforming Plant (C.C.R) in the country, by the oil company YPF. The project demanded the largest investment in the last 10 years in the refining sector of Argentina, and it is intended to meet the increasing demand for high-quality fuels.

The new C.C.R. plant has state-of-the-art features, similar to the ones that have been adopted by most global oil companies, and led to improvements in terms of productivity, safety and environmental protection.

About 700 people will be employed for the construction of the new plant, which required 34 months of work and will start operating in 2012. The production rate will be 200,000 tons of aromatic compounds a year, which can be used as gasoline octane improvers, intended for automotive use.

Likewise, it will produce 15,000 tons of hydrogen a year, which will allow the processing of hydrogen for fuel to improve the quality and decrease the content of sulfur, further reducing the environmental impact of internal combustion engines.

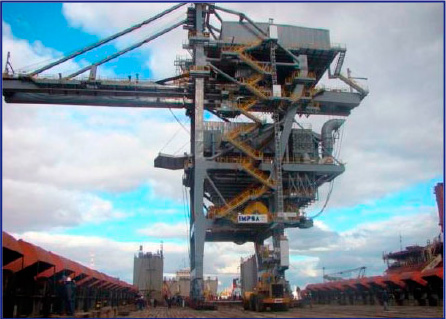

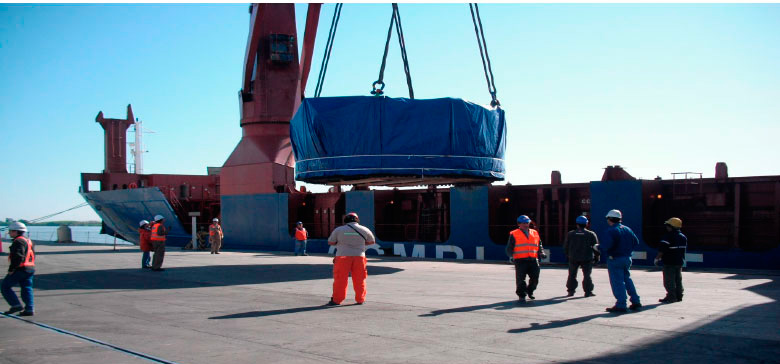

The export of a 30-million-USD Ship Unloader Gantry Crane for Alcoa World Alumina Brasil Participacoes Ltda., had the Port of Sao Luis do Maranhao, Alumar, as the destination port.

We handled one of the most important shipments in the country, with a total weight of 1,800 tons, 65 m in height, 25 m in width and 85 m in length.

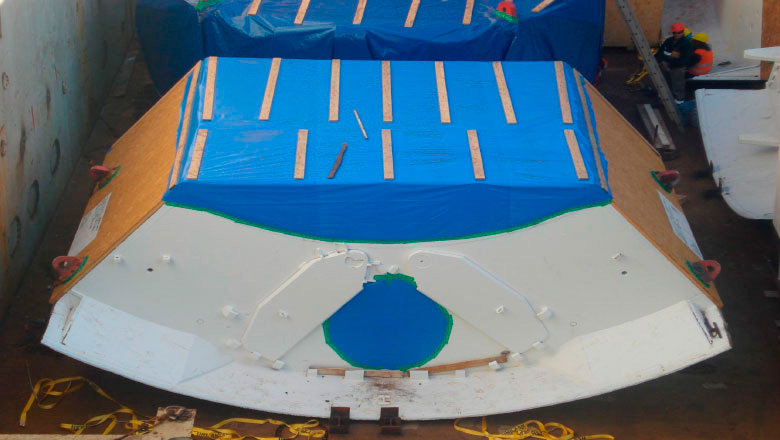

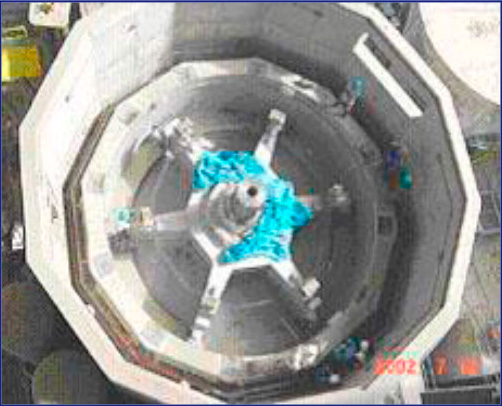

On August 16, 2011, we began the transfer of the first star of 10 turbines of Kaplan that IMPSA Industrias Metalúrgicas Pescarmona S.A. is exporting for Tocoma Hydroelectric Power Plant, in Venezuela.

This piece, which is 11 meters in diameter and 110 tons in weight, required a complex logistics transfer from the company's plant in Godoy Cruz, Mendoza, to the port of Zárate.

By 2013, ten turbines in the central state of Bolivar, Venezuela will have been built, generating 223 megawatts (MW) each and 2,200 megawatts (MW) in all. It will become one of the largest projects in Latin America and a worldwide record.

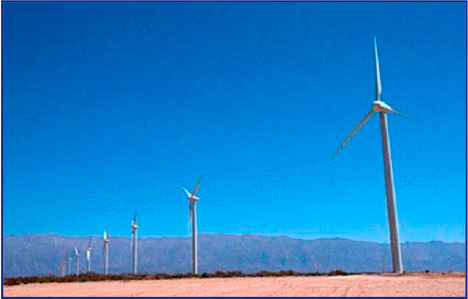

IMPSA Wind provides EPC (Engineering, Procurement & Construction) services and it supplies the equipment on a turnkey basis. This includes the supply, engineering and wind studies, the supply of 24 IWP2, 1MW wind turbines, the SCADA system for remote monitoring, a transformer substation, transportation, installation and commissioning.

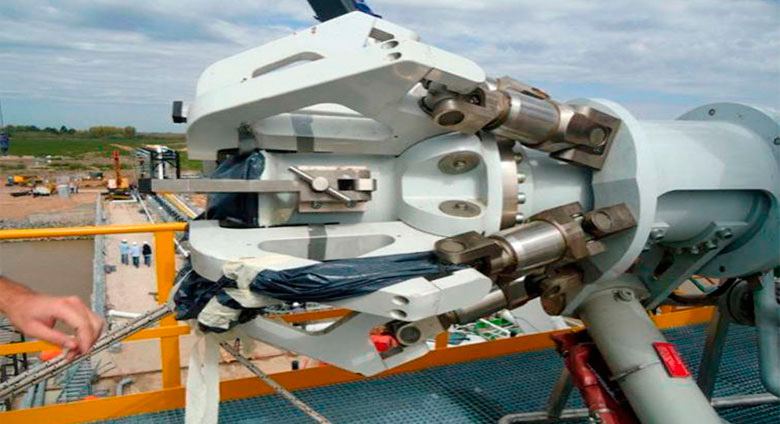

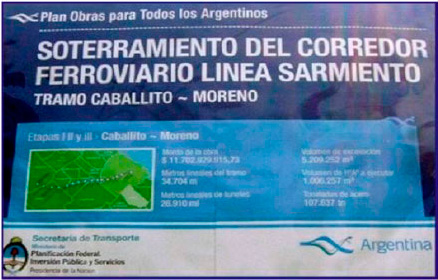

With an investment of 11,700 million USD, the works on the Undergrounding of Sarmiento Railway Line, including the construction by the Consorcio Nuevo Sarmiento (CNS) U.T.E. IECSA, Construtora Norberto Odebrecht, COMSA and Ghella SpA, consisted of 32.6 kilometers of tunnels under its current trace and the revamping of all underground stations connecting Caballito with Moreno. In this initial stage, we shipped a 2,100-ton tunneling machine from Germany (12.5 meters in diameter and 125 meters in length) through the Port of Zárate, for a value of 12 million EUR.

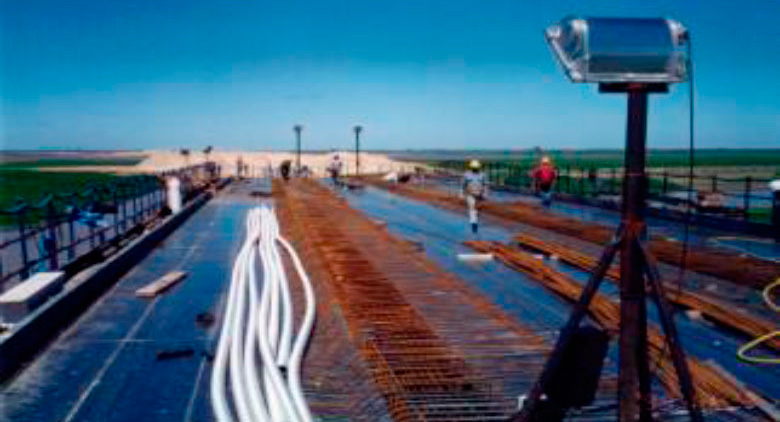

Container Terminal Project at the Port of La Plata

Container Terminal Project at the Port of La PlataIt is the most important Port Work of the last one hundred years.

The project of the Terminal at the Port of La Plata required an investment of 385 million USD, and its completion took more than three years. The work belongs to International Container Terminal Services Inc. (Ictsi) For a total value of 80 million USD, we have recently shipped four Gantry Cranes, seven Patio Cranes and other equipments to serve the internal logistics of the Terminal in the stowage area.

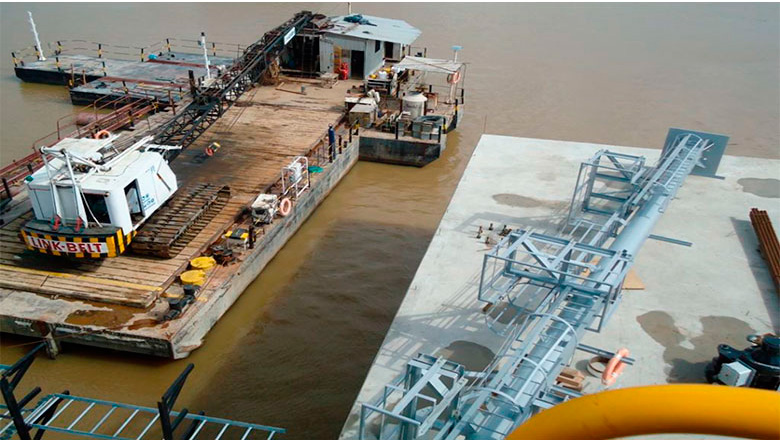

Florencio Randazzo with the Governor of Buenos Aires, Daniel Scioli, and the Mayor of General Pueyrredón, Gusto Pulti and the Production Minister of Buenos Aires Province, Cristian Breitenstein, visited the Chinese teams that performed the dredging of the Port of Mar del Plata.

The work was in charge of SERVIMAGNUS S.A. - SDC DO BRASIL SERVICIOS MARITIMOS Ltda. - ROWING S.A. and SERVIDRAGA S.A. UTE. To execute this work we had to temporarily import the Beng Hai Xin Hang Bo Dredger and the 2002 and 2003 Hang Bocame Barges from China after a three- month voyage.

The funding for the work responds to a policy laid down by Governor Scioli and the National Government of Argentina to double the capacity of the ports in the Province of Buenos Aires.

Solar San Juan is the large project of San Juan Governor, Jose Luis Gioia, to turn San Juan into the largest producer of solar panels in South America. It will comprise all the steps for the assembling of panels: cells, panels, wafers and ingots. The whole process was handled by the German company Schmid Group, experts in solar panels.

The factory will occupy 15,000 square meters and will be located in the industrial park of 9 de Julio. It will have 3 production lines that will use 567 tons of solar silicon per year and will employ about 300 people. The total investment is about139 million EUR.

Experience in Relevant Projects

There is considerable amount of projects that we have implemented over the years. For this reason, as a corollary of our presentation, and after having already mentioned the most recent ones, we will point out those that have marked the success of our company.

EL CHOCÓN HYDROELECTRIC COMPLEX - CERROS COLORADOS

HIDRONOR HIDROELÉCTRICA NORPATAGÓNICA S.A. COMPAÑÍA CONSTRUCTORA DE EL CHOCÓN, IMPREGILO - SOLLAZO S.A.

ALICOPA DAM COMPLEX AND ALICURA HYDROELECTRIC POWER PLANT

HIDRONOR HIDROELÉCTRICA NORPATAGÓNICA S.A. COMPAÑÍA CONSTRUCTORA DE EL CHOCÓN, IMPREGILO - SOLLAZO S.A.

PIEDRA DEL ÁGUILA HYDROELECTRIC PROJECT

HIDRONOR HIDROELÉCTRICA NORPATAGÓNICA S.A. UNIÓN CONSTRUCTORES ARGENTINOS S.A. JOSÉ CARTELLONE CONSTRUCCIONES CIVILES CONEVIAL S.A. - CODI S.A. - IGLYS S.A. SOLLAZO HNOS. S.A. - SUPERCEMENTO S.A. - IMPREGILO S.p.A.

PALEOBED WORK – ALLUVIUM AREA PIEDRA DEL ÁGUILA HYDROELECTRIC PROJECT

HIDRONOR HIDROELÉCTRICA NORPATAGÓNICA S.A. SOLBA U.T.E. SOLETANCHE ENTREPRISE DE ARGENTINA Y SONDAGES INJESTIONS FORDAGES S.I.F. ENTREPRISE BACHY S.A.

ARROYO URUGUA- I HYDROELECTRIC POWER PLANT CLIENTES IGLYS S.A. - IMPSA

Urugua-i Dam was meant to take advantage of a large waterfall in one of the mightiest rivers of the province of Misiones. This Hydroelectric Power Plant has been the largest civil work in the interior of the province of Misiones up to the present.

POTRERILLOS PROJECT (MENDOZA)

COMPREHENSIVE LEVERAGING OF RÍO MENDOZA. CONSORTIUM: JOSÉ CARTELLONE CONSTRUCCIONES CIVILES S.A., INDUSTRIA METALURGICA PESCARMONA S.A CONSORTIUM: JOSÉ CARTELLONE CONSTRUCCIONES CIVILES S.A., INDUSTRIAS METALÚRGICAS PESCARMONA S.A.

Location: Mendoza River, Province of Mendoza, Argentina. Project Investment: 310 million USD

The Potrerillos Project included the construction of Potrerillos Dam Reservoir, the new Cacheuta Hydroelectric Power Plant, the enlargement and modernization of Álvarez Condarco Hydroelectric Power Plant and other complementary facilities.

The Dam Reservoir, which is a concrete-faced rockfill dam (CFRD), is 116 m high and 470 m in crowning and it allowed the formation of a reservoir with a total volume of 450 Hm3 and a water mirror of 1,300 hectares; benefiting irrigation (75,000 hectares), ensuring the provision of drinking water and generating 850 GWh of energy (20% of the consumption in the Province of Mendoza).

"CBK" HYDROELECTRIC PROJECT CALIRAYA -BOTOCAN -KALAYAAN

Client:IMPSA Location:Island of Luzon, Philippines. Investment: 500 million USD

CBK Power Corporation, a partnership between IMPSA and Edison Mission in the United States, aimed at the development, financing, rehabilitation, construction, and operation and maintenance of Caliraya, Botocan and Kalayaan I and II Hydroelectric Power Plants, through a Construction, Rehabilitation, Operation and Transfer (BROT) Agreement with National

Client:IMPSA Location:Masinagudi, 150 km from Coimbatore, in the district of Nilgiris, State of Tamil Nadu, India

The Pykara Plant consists of 3 Pelton turbines of 57.2 MW each. With a waterfall of 1,200 meters, they are the turbines with the largest fall created by IMPSA. Their main feature is that they were manufactured from only one piece.

Client: IMPSA Type of Contract: Turnkey. Installed capacity: 2800 MW Location: On Balui River, about 37 km from the city of Belaga, in the Province of Sarawak, Borneo Island, Malaysia

The largest venture in Southeast Asia. The equipment supplied by IMPSA has an average power of 350 MW over the customer's requirements.

These Francis turbines, with an efficiency of over 94%, are the most efficient in the world. It is worth mentioning that the combined cycle plants, which have a maximum efficiency of nearly 60%, are the second most efficient after hydroelectric power plants.

Client: IMPSA Type of Contract: Modernization and refurbishment. Installed capacity: 615 MW Location: On the Hongshui River, 27.6 kilometers north of Beilongtan Power Plant and 83 Km south of Yantan Power Plant in Guangxi.

A new design that solves serious mechanical and hydraulic problems in the original equipment. This increased the power of these turbines from 104 MW to 123 MW, i.e. 4% higher than the value guaranteed by contract.

Client: IMPSA Location: the Caroní River, State of Bolívar, Puerto Ordaz, Venezuela.

Macagua Hydroelectric Power Plant was destined to be closed; however, thanks to a joint initiative of CVGEDELCA and IMPSA, it was renewed and its power capacity was increased by 30%. In addition, IMPSA provided a hydraulic and electromechanical laboratory under an EPC contract.

Client: IMPSA Type of Contract: Water to Wire -W2W Installed capacity: 437 MW Location: On Araguari River, Minas Gerais, Brazil

It represents the integration of all W2W technology developed by IMPSA. CEMIG, the power company of Minas Gerais, is one of the largest electricity groups in Latin America and a global leader in sustainability according to the Dow Jones index of the New York Stock Exchange.

TRANSMISSION LINES

ALICURA - ABASTO PIEDRA DEL AGUILA - ABASTO (FORTH LINE) Client: Hidronor Hidroeléctrica Nortpatagónica S.A.

ITA-GARABI Client: Compañía de Transmisión del Mercosur (ENDESA Group)

YACIRETA - RESISTENCIA CROSSING OF PARANA RIVER Client: Tenenge Técnica Nacional de Enegenharia S.A.

TRANSMISSION SYSTEMS ASSOCIATED TO YACYRETA HYDROELECTRIC PLANT, THIRD INTERCONNECTION TRUNK RINCON SANTA MARIA - RODRIGUEZ

Client: LITSA Líneas de Transmisión del Litoral ABB S.A.

TURNKEY PLANTS

OLEFIN PRODUCTION PLANT Client: Petroquímica General Mosconi S.A.

P.E.T. PRODUCTION PLANT Client: Petroquímica General Mosconi S.A.

D.M.T PRODUCTION PLANT Client: Petroquímica General Mosconi S.A.

ENLARGEMENT OF LUJAN DE CUYO YPF S.A. DISTILLERY Client: YPF S.A.

ENLARGEMENT OF LA PLATA DISTILLERY - YPF S.A. Client: YPF S.A.

TURNKEY PLANTS

GAS POWER PLANT Client: HANOVER CORPORATION Monteagudo, Bolivia

ROSARIO - VICTORIA FIXED LINK

SECRETARIAT OF PUBLIC WORKS PUENTES DEL LITORAL S.A. (CONSORTIUM: IMPREGILO - IGLYS -HOCHTIEF A.G.V.G. HELFMANN -BENITO ROGGIO E HIJOS - SIDECO - IECSA AND TECHINT)

SHIPMENT OF RENFE FREIGHT LOCOMOTIVES Spain

Client: Buenos Aires al Pacífico S.A. (BAP)

CONTRACT NO. 394 ENLARGEMENT OF "D" SUBWAY LINE

Client: Subterráneos de Buenos Aires VOEST ALPINE Argentina S.A.

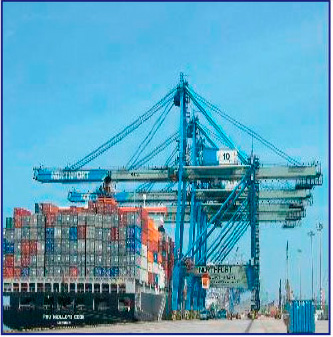

IMPORT - EXPORT OF CONTAINER CRANES

IMPSA PORT SYSTEM

* TECON CONTAINER TERMINAL, SANTOS, BRAZIL * PARANAGUA CONTAINER TERMINAL, BRAZIL * SEPETIVA TECON S.A., BRAZIL * PORT OF RIO GRANDE, TECON RIO GRANDE S.A. * PORT OF DAGANG, APP GROUP, CHINA * PORT OF RIZHAO, RIZHAO PORT AUTHORITY, CHINA * PORT OF LIANYUNGANG, LIANYUNGANG HARBOUR AUTHORITY, CHINA * NINGBO PORT, INTERNATIONAL TENDERING CO., CHINA * PORT OF SHANGHAI, SHANGHAI MACHINERY & EQ. TENDERING, CHINA TENDERING, CHINA * PORT OF CARTAGENA, SOCIEDAD PORT. REG. DE CARTAGENA, COLOMBIA * PORT OF LA HABANA, PEREZ & CIA., CUBA * PORT OF HAINA, S.E.O.P. Y C., THE DOMINICAN REPUBLIC * PORTS OF NEW ORLEANS, CONCORD, HADLOCK, HOUSTON, BALTIMORE, JACKSONVILLE, USA. * PORT OF PELABUHAN, CONTAINER HANDLING SURUBAYA, INDONESIA * PORT OF MERAK, I.P.K.K., INDONESIA * PORTS OF MALAYSIA, MEXICO, SAUDI ARABIA, SRI LANKA

IMPORT OF CONTAINER CRANES. PORT OF ZARATE

BANCO DE GALICIA Y BUENOS AIRES S.A. MURCHISON S.A.

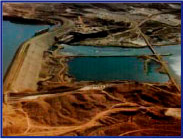

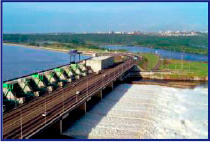

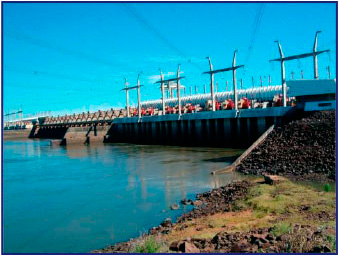

SALTO GRANDE HYDROELECTRIC DAM (ARGENTINA -URUGUAY)

Client: Empresa Constructora Salto Grande S.A. led by IMPREGILO, the company which constructed Salto Grande Binational Hydroelectric Project between Argentina and the Uruguay on the Uruguay River. Amount: 400,000,000 USD.

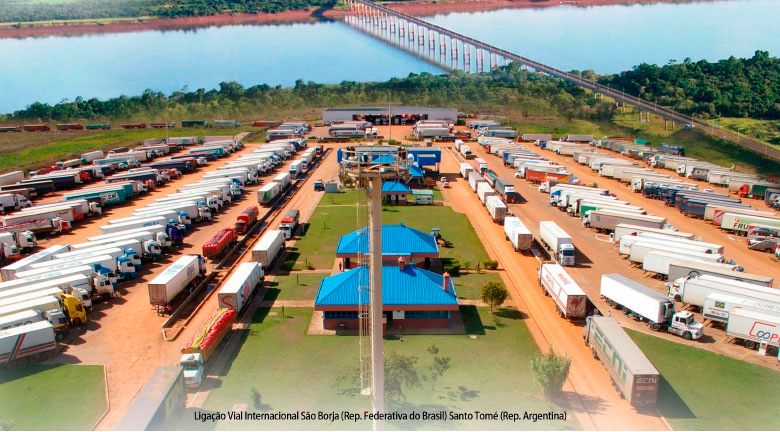

SANTO TOME SAO-BORJA INTERNATIONAL INTEGRATION BRIDGE (MERCOSUR) MERCOVIA S.A., IMPREGILO

El The Integration Bridge is an international viaduct on the Uruguay River, which connects the cities of Santo Tome (Argentina) and Sao Borja (Brazil). The bridge is connected to Ruta Nacional 121 on the Argentine side (9 km of the National Road), and the Ruta Nacional 285 on the Brazilian side.

The work in question involved the construction of the bridge, and the creation of the first unified customs center in the MERCOSUR. The total cost of the project was 40 million USD, 16 million of which were provided in equal parts by the Brazilian and Argentine States, and the rest by Mercovia S.A., the consortium that built the bridge and currently operates it.

The consortium that was responsible for the construction and operation of the bridge was led by the Italian company Impregilo and its subsidiaries in Argentina (Iglis) and Brazil (Cigla). These add up to a 51% representation, while the remaining percentage is for the following companies: Necom (19%), Usifast (10%) and Chediack (19%).

Opened on December 9, 1997 with the presence of the then president Carlos Menem and Fernando Henrique Cardoso, one of the objectives of this bridge was to reduce the heavy traffic that had been moving through Paso de los Libres until then. i.e. 80% of road traffic between Argentina and Brazil was through Paso de los Libres International Bridge Getulio Vargas - Augustine P. Justo.

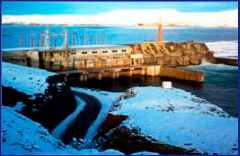

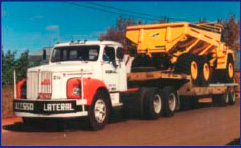

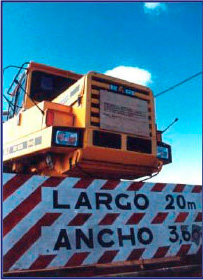

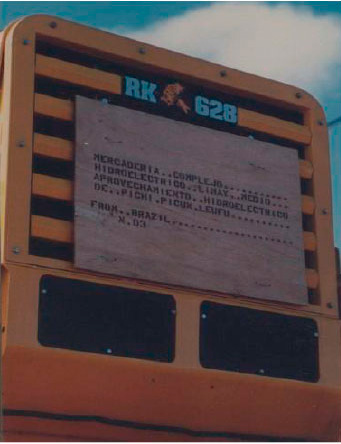

HYDROELECTRIC LEVERAGING OF PICHI PICUN LEUFU (MERCOSUR) CONSORCIO PATAGONIA U.T.E.

Client: Construtora Nortberto Odebrecht, Benito Roggio y Otros U.T.E.

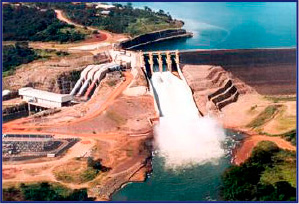

The first challenge for Odebrecht in Argentina was the execution of the Pichi Picún Leufú Hydroelectric Plant on the Limay River (on the border between the provinces of Neuquén and Rio Negro), 250 km from the city of San Carlos de Bariloche. The plant has an installed capacity of 261 MW, comprising a dam, 6 spillway gates per sector, an engine room, three generation units, a water intake and a service bridge.

In the consortium through which the project was carried out, with Hidronor as a client, Odebrecht was the leader. The work involved the participation of about 2,000 people.

HYDROELECTRIC LEVERAGING OF PICHI PICUN LEUFU (MERCOSUR) CONSORCIO PATAGONIA U.T.E.